Poor Man's Road Draft Tube to PCV Conversion

Introduction

During the combustion cycle of a 4-cycle gasoline engine, a certain amount of blow-by gasses get past the piston rings and into the cavity of the engine block. Modern cars use a system called PCV or Positive Crankcase Ventilation to prevent the gasses from accumulating inside the engine. On early 1962 and earlier Thunderbirds, these gasses were vented to the atmosphere via a "road draft tube" that was connected to the back of the intake manifold. The idea of operation was that when the car was moving, the draft across the bottom of the tube would create a slight vacuum and pull the gasses out of the crankcase. This system, of course, did not work while the engine was stopped and idling. Another problem with the draft tube is that it is right in front of the passenger's compartment and could allow noxious gasses to enter the cabin. PCV was instituted for two reasons. The first being an environmental consideration; to keep the gasses from venting to the atmosphere. However, PCV also has a second benefit, it keeps the inside of the engine cleaner.

A PCV valve is quite simple. An internal restrictor (generally a cone or ball) is held in "normal" (engine off, zero vacuum) position with a light spring, exposing the full size of the PCV opening to the intake manifold. With the engine running, the tapered end of the cone is drawn towards the opening in the PCV valve by manifold vacuum, restricting the opening proportionate to the level of engine vacuum vs. spring tension. At idle, the intake manifold vacuum is near maximum. It is at this time the least amount of blow by is actually occurring, so the PCV valve provides the largest amount of (but not complete) restriction. As engine load increases, vacuum on the valve decreases proportionally and blow by increases proportionally. With a lower level of vacuum, the spring returns the cone to the "open" position to allow more air flow. At full throttle, vacuum is much reduced, down to between 1.5 and 3" Hg. At this point the PCV valve is nearly useless, and most combustion gases escape via the "breather tube" where they are then drawn in to the engine's intake manifold anyway. (http://en.wikipedia.org/wiki/Crankcase_ventilation_system).

The parts to install the correct system are available from used Thunderbird parts suppliers. Until I get the correct parts, this is the system I cobbled together.

The view on the left shows the road draft tube mounted in the back of the manifold where it turns and goes to the underside of the car. The complete tube is pictured on the right.

I removed the manifold and removed the elbow. As can be seen, it is full of oil sludge. The underside of the manifold is heavily varnished. This presents a problem for oil cleanliness as well as cooling.

The views below show the valley pan, a cover that controls the flow of air in the crankcase, and the back of the block with the valley pan removed. The sludge accumulation was not severe and was cleaned with a rag and some engine degreaser.

I cleaned the manifold and valley pan and painted the manifold the correct semi-gloss black and installed the elbow before installing the manifold onto the engine.

The inner diameter of the elbow was exactly 1". I began to look around my garage for some kind of pipe of that outer diameter. I found a piece of 3/4" plastic irrigation pipe the fit the bill perfectly. I cut a 1" piece out of it to slip inside the elbow. Into that will go an EV50 or the equivalent Fram FV156 PCV valve.

This is the Fram FV156 valve inserted into the pipe and then into the elbow. The inner diameter of the pipe was a little larger than 3/4" and the outer diameter of the valve was exactly 3/4" I used a few wraps of teflon tape to make a snug fit of the valve inside the pipe. Also worth noting is the diameter of the hose nipple on the valve. It accommodates a 1/2" hose. This will match the diameter of the carburetor baseplate port below.

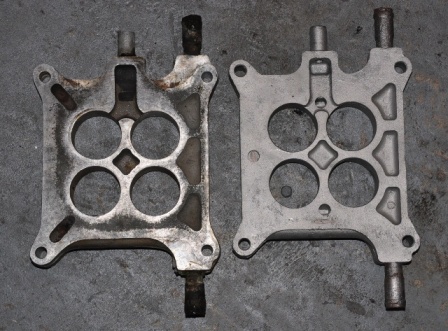

There were two different carburetor baseplate castings for 1962. On the left is C2SE-9A589-A, without the PCV port and on the right is C2SE-9A589-B, with the PCV port. I obtained the B-casting baseplate from Ebay several years ago for $7.00.

Here is the complete system with the 1/2" fuel-grade line running from the PCV to the baseplate. Although this is not the correct PCV system for the car, it basically cost me $11.00. $3.00 for the PCV valve, $7.00 for the baseplate, and $1.00 for the 1/2" hose.